Commercial Kitchen Ventilation Requirements Guide

Share

Think of a commercial kitchen without proper ventilation. It wouldn't take long for the space to become a hot, smoky, greasy mess. That's why having a professionally designed ventilation system isn't just a good idea—it's an absolute necessity for safety, air quality, and staying on the right side of the law.

These systems are your non-negotiable fire prevention tool, designed to pull dangerous grease-laden vapors, intense heat, and smoke out of your kitchen. Get it wrong, and you could be looking at hefty fines, a forced closure, or worse, a devastating fire.

Why Kitchen Ventilation Is Non-Negotiable

A good way to think about it is that your ventilation system is the lungs of your kitchen. It's constantly breathing out the contaminated air and pulling in fresh, clean air. This isn't just about comfort; it's a critical safety function that makes the whole operation possible.

Before we dive into the technical rules, it’s crucial to understand why they exist. Complying with commercial kitchen ventilation requirements is more than just passing an inspection. It's about actively protecting your people, your customers, and your entire business from disasters that are entirely preventable.

The Overlooked Dangers of Poor Ventilation

Every time you fire up your cooking equipment, you're releasing a whole cocktail of byproducts into the air. Without a powerful exhaust system right at the source, those contaminants have nowhere to go. They just build up, creating a pretty nasty environment with serious consequences.

You're essentially looking at three major risks when ventilation is subpar:

- Fire Hazards: The biggest threat is grease-laden vapor. As this greasy steam cools, it turns back into a sticky solid, coating your ductwork with a highly flammable fuel. It's no surprise that the National Fire Protection Association (NFPA) reports that cooking equipment is the number one cause of fires in restaurants and bars.

- Health and Safety Risks: All that smoke and steam can cause real respiratory problems for your staff. On top of that, excessive heat leads to exhaustion and kills focus, which is a recipe for accidents. Poor air quality even impacts food safety when airborne grime settles on prep surfaces.

- Structural and Equipment Damage: Constant heat and humidity are tough on a building. Trapped moisture can lead to mold and mildew, while the lingering heat can cause expensive refrigerators and other essential equipment to burn out way too soon.

A properly engineered ventilation system is the first and most effective line of defense against kitchen fires. By continuously removing grease before it can accumulate, the system mitigates the primary fuel source for a potential blaze.

At the end of the day, a ventilation system isn't just another piece of equipment; it's an integrated safety feature. It works around the clock to handle the extreme conditions that only a commercial kitchen can produce. Keeping that in mind is key to understanding why meeting these requirements is just a fundamental part of running a successful restaurant.

Decoding Key Regulations and Safety Codes

Diving into the world of commercial kitchen ventilation can feel like trying to read a foreign language. But once you grasp the simple idea behind all the rules, it all starts to click. At their core, these regulations are about one thing: fire prevention.

Think of these codes less as red tape and more as a safety blueprint. They provide a proven system for handling the single most dangerous element in a commercial kitchen—grease-laden vapor. Following these guidelines is hands-down the best way to protect your people, your customers, and your entire business from a devastating fire.

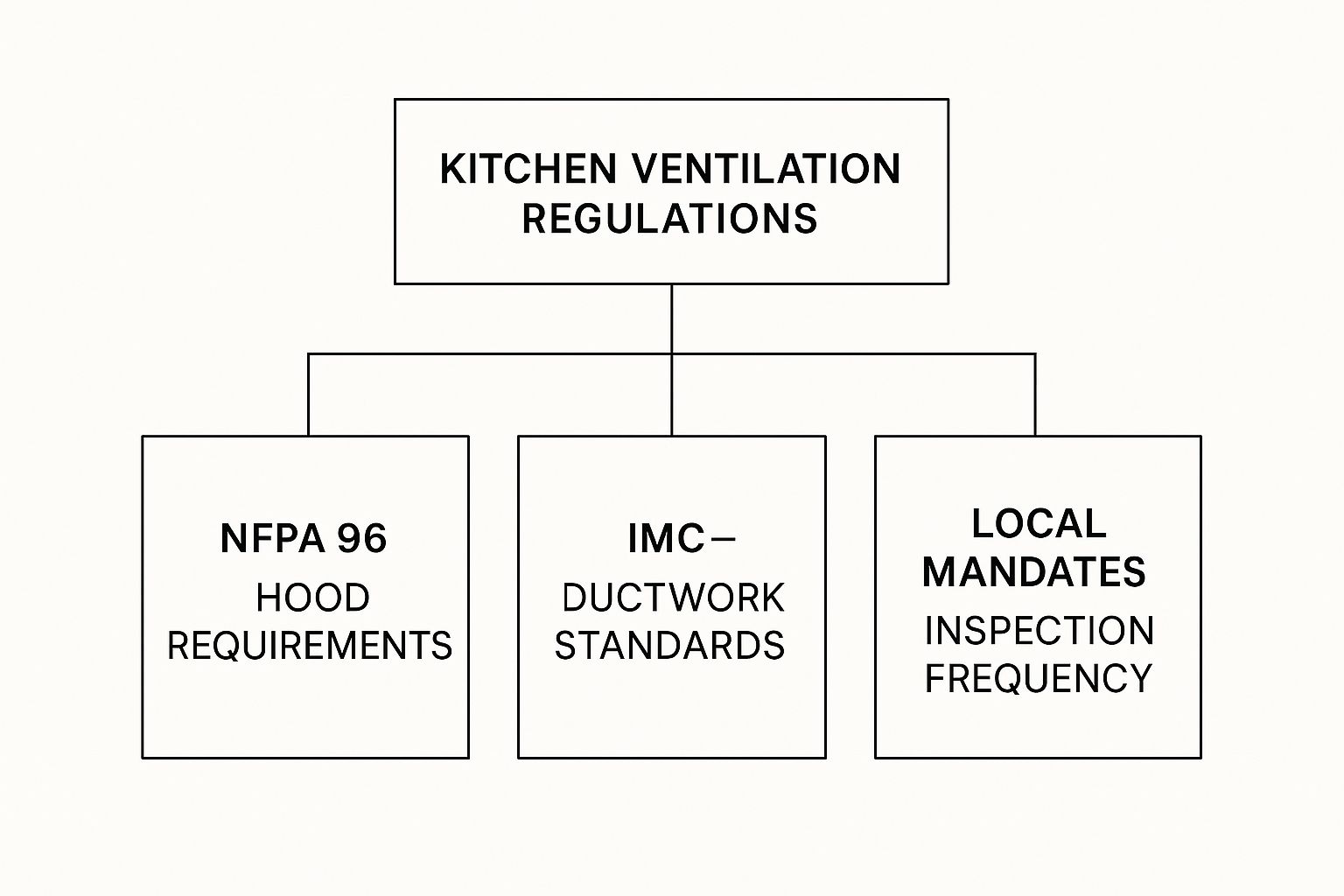

This diagram shows how it all fits together, with national standards like NFPA 96 and the IMC setting the baseline, and local authorities adding their own rules on top.

As you can see, staying compliant isn't just a one-and-done deal. It’s a layered process that involves choosing the right equipment and keeping up with local rules for inspections and maintenance.

The Gold Standard: NFPA 96

When it comes to fire safety in commercial kitchens, one document is the undisputed champion: NFPA 96, Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations. This is the bible for fire marshals, inspectors, and system designers across the country. These aren't just recommendations; they are non-negotiable safety protocols.

For decades, NFPA 96 has been a game-changer in reducing kitchen fires. In the U.S., the National Fire Protection Association has long required proper exhaust systems to pull dangerous vapors out of the kitchen. NFPA 96 gets specific, demanding integrated hoods, ducts, fans, and fire suppression systems built to stop flammable grease from building up. You can dig deeper into these critical safety standards and their history.

NFPA 96 is incredibly thorough, covering every piece of the ventilation puzzle. Here's what some of its most important rules mean in the real world:

- Proper Hood Placement: The hood needs to hang over the cooking line, extending past the edges of the equipment. This creates a capture zone for all the rising smoke, heat, and grease.

- UL Listed Grease Filters: Your filters can't be just any old screen. They must be UL listed, which proves they can trap grease effectively and won't go up in flames.

- Sealed Ductwork: All ducts have to be made of steel with liquid-tight, continuously welded joints. This basically turns the ductwork into a sealed metal tube, ensuring flammable grease can't leak out and drip onto flammable materials in your ceiling or on your roof.

Understanding the International Mechanical Code

While NFPA 96 is laser-focused on fire protection, the International Mechanical Code (IMC) takes a broader view of the system's mechanical health. The IMC and NFPA 96 work together. One ensures the system won't start a fire, and the other ensures it’s mechanically sound and actually cleans the air.

The IMC dictates things like how the ductwork is built, how powerful the fan needs to be, and how the makeup air system works. For instance, it specifies the minimum air speed needed to keep grease particles floating all the way out of the building instead of settling and creating a fire hazard inside the ducts.

"Think of NFPA 96 as the fire safety expert and the IMC as the mechanical engineer. You need both on your team to build a system that's safe, effective, and up to code. If you ignore one, you've got a major gap in your kitchen's safety."

The Role of Local Health and Fire Departments

The final piece of the puzzle is your local jurisdiction. The city or county fire marshal and the health inspector are the people who will actually walk through your kitchen and give you the green light.

While they work from the NFPA and IMC playbooks, local departments often add their own specific rules to the mix. These might include:

- Stricter Inspection Frequencies: They may require professional cleanings more often than the minimums in NFPA 96, especially in high-volume kitchens.

- Permitting Processes: They have their own requirements for plans, documents, and engineering reports you need to submit before you can even start construction.

- Specific Equipment Mandates: Some areas might have unique rules about the types of fire suppression systems or alarm connections you have to use.

It is absolutely crucial to talk to your local fire and building departments early in the design phase. They can give you a clear checklist of what they’ll be looking for, saving you from expensive mistakes and frustrating delays down the road. Getting a local code wrong can mean failing an inspection and having to tear out and redo perfectly good work. At the end of the day, these codes aren't there to make your life harder—they're there to keep everyone safe.

The Anatomy of a Ventilation System

A commercial kitchen ventilation system is far more than just a powerful fan. It’s a sophisticated, interconnected network where every single part has a critical job to do. If one component isn't performing correctly, the safety and efficiency of the entire kitchen are on the line. Getting a handle on this anatomy is the first step to mastering commercial kitchen ventilation requirements.

Think of it as a respiratory system for the kitchen. It works around the clock to capture, contain, and safely expel the hazardous grease-laden vapors, intense heat, and smoke that are byproducts of a busy cook line. Let's trace the journey of the air, from the moment it rises off a hot grill to its final exit, to see how each piece plays its part.

The First Line of Defense: The Exhaust Hood

The exhaust hood is the most recognizable component, acting as the system's frontline defense. Positioned directly above the cooking appliances, its job is to create a massive capture zone—essentially a giant, inverted funnel that snags hot, greasy air before it can escape and contaminate the kitchen environment.

Hoods aren't one-size-fits-all. They come in two primary types, each engineered for a specific task:

- Type I Hoods: These are the heavy-duty workhorses. They're mandatory for any equipment that kicks out grease or smoke, like charbroilers, fryers, and griddles. Their design is centered on fire safety and is the main focus of stringent standards like NFPA 96.

- Type II Hoods: Often called condensate hoods, these are for appliances that only generate steam and heat, such as conveyor dishwashers or some ovens. They manage moisture, not flammable grease.

The placement and size of a hood are no accident. Codes require it to overhang the cooking equipment by a specific amount, usually at least six inches on all sides, to guarantee it can effectively capture everything rising from the surfaces below.

The Grease Trappers: Baffle Filters

As soon as the grease-filled air enters the hood, it hits the baffle filters. These are cleverly designed metal plates arranged in a maze-like pattern, forcing the air to change direction sharply and repeatedly.

This sudden movement works like a centrifuge. The heavier grease particles can't make the tight turns, causing them to slam into the steel baffles, where they liquefy, cool, and drain safely into a collection tray. These filters are the system’s kidneys, constantly pulling out the most dangerous materials. Clogged filters choke the airflow, cripple the system's efficiency, and create a massive fire risk, which is why daily or weekly cleaning is absolutely non-negotiable.

The Transportation Network: Ductwork

After passing through the filters, the air—still hot but with most of the grease removed—is pulled into the ductwork. This network of sealed metal channels is the superhighway that transports contaminated air from the kitchen to the building's exterior. To get a better feel for the mechanics, it helps to understand the fundamentals of MEP engineering.

Under NFPA 96 guidelines, this ductwork must be made of steel and feature liquid-tight, continuously welded joints. This is an absolutely critical fire safety feature. It ensures that if any residual grease manages to condense inside the ducts, it can't leak out and ignite flammable materials hidden in wall cavities or ceiling spaces.

The Engine Room: The Exhaust Fan and Makeup Air Unit

The exhaust fan is the heart of the whole operation. Usually mounted on the rooftop, this powerful motor creates the negative pressure needed to pull air all the way from the cooktop, through the hood, filters, and ducts, before finally expelling it outside. Its capacity is measured in Cubic Feet per Minute (CFM) and must be precisely calculated to match the kitchen's specific exhaust needs.

But you can’t just pull air out of a building without putting some back in. That's the job of the makeup air (MUA) unit. This equally vital piece of equipment pulls fresh, conditioned air from outside and pumps it back into the kitchen, typically replacing 80-90% of the air being exhausted.

Without a properly functioning makeup air unit, the kitchen would turn into a negative-pressure vacuum. This dangerous situation can cause exhaust hoods to fail, extinguish pilot lights, create carbon monoxide buildup, and even make it difficult to open doors—a major safety hazard for staff.

Together, these components create a balanced, life-saving system that no commercial kitchen can operate without.

Key Ventilation System Components and Their Functions

To bring it all together, here is a quick breakdown of the essential parts of a commercial kitchen ventilation system, what they do, and a key compliance note for each.

| Component | Primary Function | Key Compliance Note (NFPA 96) |

|---|---|---|

| Exhaust Hood | Captures heat, smoke, and grease-laden vapor at the source (cooking equipment). | Must overhang cooking surfaces by a specified distance (typically 6 inches) to ensure effective capture. |

| Baffle Filters | Removes grease particles from the airstream through impingement. | Must be constructed of steel or other approved non-combustible material and be easily removable for cleaning. |

| Ductwork | Safely transports contaminated air from the hood to the exhaust fan. | Must be constructed of steel (minimum 16-gauge) and have liquid-tight, continuously welded joints. |

| Exhaust Fan | The motor that pulls air through the system and expels it outdoors. | Must be listed for commercial cooking applications and have a weatherproof housing if installed outdoors. |

| Makeup Air (MUA) Unit | Replaces exhausted air with fresh, tempered air to maintain kitchen pressure. | Required to prevent negative air pressure; must supply air without affecting hood capture performance. |

| Fire Suppression System | Automatically detects and extinguishes fires within the hood and ductwork. | Must be integrated with the ventilation system to automatically shut off fuel/power to appliances upon activation. |

Understanding how these parts work in concert is crucial for designing, installing, and maintaining a system that keeps a kitchen safe, clean, and compliant.

Designing and Sizing Your System Correctly

Think about using a garden hose to put out a roaring warehouse fire. It’s obviously the wrong tool for the job. The same logic holds true for your kitchen's ventilation. A system built for a small café's pastry oven would be completely overwhelmed—and dangerously ineffective—in a steakhouse with a bank of high-volume charbroilers.

When it comes to commercial kitchen ventilation, there’s no such thing as "one-size-fits-all." Taking that approach is a fast track to system failure, code violations, and a hazardous work environment.

The heart of any good system design is its ability to move the right amount of air. We measure this in Cubic Feet per Minute (CFM), which is simply the volume of air the system pulls out of the kitchen every single minute. Nailing this number is a delicate balance. Go too low, and you’ll leave smoke and grease hanging in the air. Go too high, and you’re just pulling expensive heated or cooled air right out of the building.

Calculating Your Kitchen's Airflow Needs

So, how do the pros figure out the perfect CFM for a kitchen? It’s not a ballpark guess; it's a careful calculation based on several key factors. Engineers look at the entire cooking operation to design a system that can handle the kitchen's unique workload.

The main things that drive the CFM calculation are:

- Appliance Type and Heat Output: A gas-fired charbroiler churning out heavy smoke and grease particles needs a much higher exhaust rate than a simple electric convection oven.

- Kitchen Layout: The way your cooking line is set up matters. A hood over a center island, for example, needs to be more powerful than one mounted against a wall because it has to fight cross-drafts from all directions.

- Cooking Volume: How much and how often you cook has a huge impact. A bustling restaurant that’s firing on all cylinders from open to close places a far greater demand on its ventilation than a kitchen with shorter, less intense service hours.

A classic rookie mistake is to focus only on the exhaust fan. But a powerful fan is totally useless if the makeup air system can't replace the air it's removing. You need a balanced system, where makeup air brings back roughly 80-90% of the exhausted air. This is critical for everything from appliance performance to employee comfort.

The Role of Makeup Air in System Balance

Just pulling air out of the kitchen is only half the battle. For every cubic foot of air your exhaust fan yanks out, you have to bring nearly a cubic foot of fresh air back in. This is the all-important job of the makeup air (MUA) unit.

Without proper makeup air, your kitchen will develop what’s called negative air pressure, which triggers a whole host of problems. It can make your exhaust hood weak and ineffective, causing smoke to spill back into the room. Even worse, it can cause dangerous back-drafting from gas appliances, pulling carbon monoxide into the workspace. It can even make doors difficult to open—a huge safety hazard in an emergency.

Properly balancing your exhaust and makeup air isn't just a good idea; it's a non-negotiable part of a safe, compliant kitchen. To get it right, it's vital to accurately calculate air changes per hour and ensure you're moving enough air for the space.

Why Professional Design Is Essential

Designing a ventilation system isn't something you can just wing. It involves complex fluid dynamics, a solid grasp of thermodynamics, and a deep knowledge of local and national codes. Simply picking the right equipment—from hoods and fans to the ductwork that connects them—is a science in itself.

For anyone outfitting a new kitchen or upgrading an old one, browsing a wide selection of Los Angeles restaurant equipment can give you a better feel for the professional-grade options available. Ultimately, investing in professional design ensures your system isn't just up to code, but is also energy-efficient and perfectly matched to your kitchen's real-world needs.

Installation Inspection and Ongoing Maintenance

A top-of-the-line ventilation system is useless if it's installed improperly or left to fend for itself. Even the most sophisticated equipment will fail to meet commercial kitchen ventilation requirements if it's put together with shortcuts or allowed to fall into disrepair. This is where the blueprints come to life and where ongoing diligence protects your people and your investment.

Think of it this way: you wouldn't buy a high-performance race car and then have it assembled by someone who only works on bicycles. The precision needed during installation is immense, and so is the need for routine tune-ups to keep it running safely.

Vetting Your Installer and Spotting Red Flags

The installation process is no place to cut corners. Your first line of defense against future headaches is a certified and experienced installer who lives and breathes this work. They'll know the ins and outs of local codes and the strict mandates of NFPA 96. When checking out a pro, look for a solid track record with kitchens just like yours.

Fire marshals are trained to spot installation mistakes from a mile away. These common red flags are often immediate grounds for a failed inspection:

- Improper Duct Welding: NFPA 96 demands liquid-tight, continuously welded seams on all ductwork. Any gaps, screws, or shoddy seals create an escape route for flammable grease, essentially turning the space above your ceiling into a hidden fire hazard.

- Incorrect Clearances: The code is incredibly specific about the distance between ventilation components and anything that can burn. For example, you generally need a minimum clearance of 18 inches from ductwork to wood, drywall, or other combustible materials.

- Poor Rooftop Fan Installation: The exhaust fan must be hinged to allow easy access for cleaning crews. It also needs a proper grease containment system to prevent that hazardous gunk from coating your roof.

Failing an inspection for any of these issues means expensive rework and frustrating delays. Getting the installation done right the first time is one of the most critical steps in the entire project.

The Non-Negotiable Maintenance Schedule

Once your system is installed and has the green light, the focus shifts to maintenance—a responsibility that truly never ends. NFPA 96 is crystal clear on this point: regular, professional cleaning isn't a suggestion, it's a requirement. Grease buildup is a given, and it's the primary fuel source for most devastating kitchen fires.

The frequency of professional cleaning is directly tied to the type and volume of cooking. A system that isn't cleaned on schedule is considered a severe fire code violation and can even void insurance claims if a fire breaks out.

Your cleaning schedule depends entirely on what you're cooking and how often. NFPA 96 provides a straightforward framework for this, which is your roadmap to staying compliant.

NFPA 96 Cleaning Frequency Guidelines

| Type of Cooking Operation | Required Inspection Frequency |

|---|---|

| Solid Fuel Cooking (e.g., wood or charcoal) | Monthly |

| High-Volume Cooking (e.g., 24-hour service, charbroiling) | Quarterly |

| Moderate-Volume Cooking (e.g., standard restaurant) | Semi-Annually |

| Low-Volume Cooking (e.g., churches, day camps) | Annually |

Remember, this schedule covers the entire system—from the hood and filters right above the cookline to the hidden ducts and the exhaust fan on the roof.

Why Your Maintenance Log Is Your Best Friend

Paperwork is your proof of diligence. Keeping a detailed maintenance log is absolutely essential for passing fire inspections and keeping your insurance provider happy. Every time your system gets a professional cleaning, you should get a detailed report or a service sticker for the hood.

This log should track:

- Date of Service: When was the work done?

- Service Provider: Who was the certified cleaning company?

- Scope of Work: What exactly did they clean (hoods, ducts, fan, etc.)?

- Deficiencies Found: Did they find any issues, like damaged parts or unusually heavy grease?

When the fire marshal walks in, they're going to ask to see this log. A clean, up-to-date record proves your commitment to safety and shows you're meeting all commercial kitchen ventilation requirements. It’s your best defense, demonstrating that you're proactively managing fire risk to protect your business, staff, and customers.

Got Questions About Your Kitchen Ventilation? Let's Clear the Air.

Even with a solid grasp of the basics, kitchen ventilation can be a tricky subject. I've been in countless commercial kitchens, and the same questions pop up time and time again. From picking the right hood to figuring out cleaning schedules, the details matter. Let's tackle some of the most common questions head-on to help you make smart decisions that keep your kitchen safe and compliant.

Getting this stuff right isn't just about passing an inspection—it's about creating a kitchen that’s safe, efficient, and a decent place to work.

What's the Real Difference Between a Type I and Type II Hood?

This is probably the number one point of confusion. The easiest way to think about it is that they are specialists built for completely different jobs.

A Type I hood, often called a grease hood, is the heavy-hitter. You absolutely must have one of these over any appliance that spits out grease or smoke—think fryers, griddles, charbroilers, and ranges. They're built for fire safety, with baffle filters designed to trap grease and a built-in fire suppression system.

On the other hand, a Type II hood (or a condensate hood) is for appliances that only produce heat, steam, and moisture. You’ll see these hanging over dishwashers or steam tables. Their job is simply to get heat and humidity out of the kitchen, not to handle flammable grease.

How Often Do I Really Need to Clean My Ventilation System?

This isn’t a suggestion; it's a hard-and-fast rule laid out in NFPA 96, and the answer depends entirely on what you're cooking and how much of it. Putting off a cleaning is one of the quickest ways to fail a fire inspection and, more importantly, create a massive fire hazard.

Here’s the breakdown of how often you need a professional inspection and cleaning:

- Monthly: If you're cooking with solid fuel like wood or charcoal, you're on a monthly schedule. No exceptions.

- Quarterly: For high-volume spots using charbroilers or woks, you'll need this done every three months.

- Semi-Annually: This is the standard for most restaurants with moderate cooking volume.

- Annually: If you're running a low-volume kitchen, like in a church, day camp, or a seasonal spot, once a year should suffice.

Always, always keep a detailed log of these professional cleanings. That logbook is your proof of compliance when the fire marshal stops by for a visit.

"A clean ventilation system is the most overlooked aspect of kitchen fire safety. Grease buildup in the ductwork is a hidden fuel source waiting for an ignition spark. Regular, documented cleaning isn't just a code requirement—it's your primary fire prevention strategy."

Can I Just Install a Used Ventilation Hood?

I get it. You're looking to save some money, and a used hood seems like a great deal. The short answer is yes, you can, but it's a risky path loaded with potential headaches.

First off, that hood must be UL listed and a perfect match for the specific cooking equipment you'll be using. Second, it has to meet all current local and national codes, which have likely changed since it was first built. You'll need a professional engineer to sign off on it, confirming it's safe and compliant for your exact setup. By the time you pay for inspections, retrofitting, and professional verification, those initial savings can evaporate quickly.

For a deeper dive, check out our guide on selecting the right restaurant equipment blog post.

What is Makeup Air and Why Is It Such a Big Deal?

Think of makeup air as the unsung hero of your entire kitchen. Your exhaust fan is constantly yanking air out of the room. Makeup air is the fresh, outside air that's brought back in to replace it. It's a balancing act.

Without enough makeup air, your kitchen develops negative pressure and basically turns into a giant vacuum. That's when all sorts of problems start:

- Your exhaust hood stops working effectively, leaving smoke and smells to hang in the air.

- Worse, you can get back-drafting from gas appliances, which can pull deadly carbon monoxide right back into the kitchen.

- It can even make your exterior doors incredibly hard to open, which is a serious safety hazard during an emergency.

A properly balanced makeup air system isn't just a nice-to-have; it's absolutely crucial for safety, comfort, and keeping your whole system running correctly.

This whole sector is only getting more important, driven by tighter regulations and a big push for energy efficiency. The global market for these systems was valued at around USD 4.51 billion in 2025 and is on track to hit USD 6.82 billion by 2032—that’s a steady growth of about 5% a year. You can read more about these market trends and projections. That growth just goes to show how critical it is to invest in a system that's both compliant and efficient.

At Restaurant Equipment SEO, we specialize in helping businesses in the food service industry stand out. Our targeted SEO strategies, from expert article writing to strategic link building, are designed to boost your online presence and connect you with qualified customers. Discover how our services can elevate your brand by visiting us at https://restaurantequipmentseo.com.